DISSOLVED OXYGEN (D.O.) SENSOR WITH MODBUS RTU COMMUNICATIONS

Unique Features highlighting technical advantages for industrial application use

- Thick-wall TEFLON membrane ensures very high stability, low-drift and high durability in aggressive industrial applications & minimizes frequency of membrane replacement

- No special maintenance needed. Just wipe the membrane periodically as required

- Galvanic dissolved oxygen cell with true zero means only slope (span) calibration is performed dry inair. No wet solution calibration is ever needed to simple field operation

- Membrane is easy to replace and electrolyte solution is simple to recharge allowing for extremely low ongoing cost of ownership and a theoretically unlimited service lifetime

- The AST-DO-UNIVERSAL D.O. sensor is not sensitive to presence of hydrogen sulfide gas

- Temperature compensation is built-in & performed automatically to ensure reliable readings

The AST-DO-UNIVERSAL smart digital MODBUS RTU dissolved oxygen sensor is a robust industrial grade sensor measures the dissolved oxygen ppm and percent (%) saturation values including salinity correction. The probe is very rugged and easy to use with automated dry in air smart calibration suitable for use in the toughest industrial, municipal, environmental and aquaculture applications.

Rugged Industrial DO Sensor for Tough Inline, Immersion & Submersible Installs

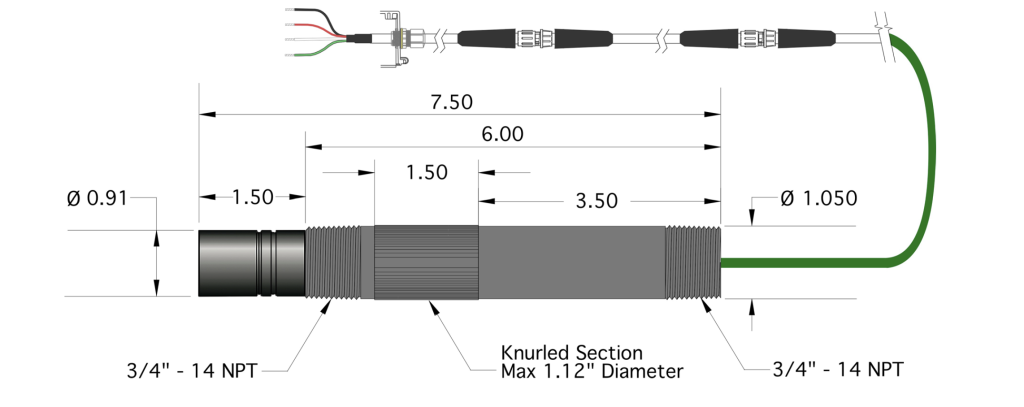

- Inline Insertion depth from 1.5 inches (standard) to 3.5 inches (special order option)

- Ready for inline or immersion use standard, submersible with waterproofing option

- Waterproofing seal option is available for complete cable isolation for fully submersible installations &applications employing field washdowns and/or moist & humid conditions

- Integral Pt1000 temperature element used to compute the percent (%) saturation values

- Integral Smart Digital MODBUS RTU digital sensor board for low-noise operation and long cable runsas well as portability of field calibrations and configurations for plug & play hot-swap

- Fully automated calibration including corrections for air pressure and ambient temperature

- Percent (%) Saturation computed with corrections for temperature, air pressure and salinity.

- Special Calibration Percent (%) Saturation excludes salinity correction for dry in air condition

- Up to 1,000 meters (3,280 feet) total cable length using HiQ4F/HiQ4M snap extensions

- Smart Digital HiQDT MODBUS RTU configuration has 6 meters (20 feet) of cable standard, Maxintegral cable length 23 meters (75 feet) cable (longer lengths possible as special orders)

- Fully submersible up to max 15 meters (50 feet) without use of an immersion rod (standpipe)

- Min and Max temp in use plus time since last calibration analytics stored. The total time in use, sensoritem number, sensor serial number including year and month of manufacture also stored integral to sensorto support remote troubleshooting with all data portable inside sensor.

- Modbus implementation guide gives details for programming PLC or data acquisition device

- ¾” MNPT Front Threads for Screw-in Inline Use (1.5” Std to 3.5” Special Order Max insertion)

- ¾” MNPT Rear Threads for Immersion Use or Submersible with Waterproofing Option