Rhinoeye Fiber-Optic Sheet Break Detection

Rhinoeye is the latest in Digital Infrared solutions for non-contact reliable detection of sheet breaks on a paper machine.

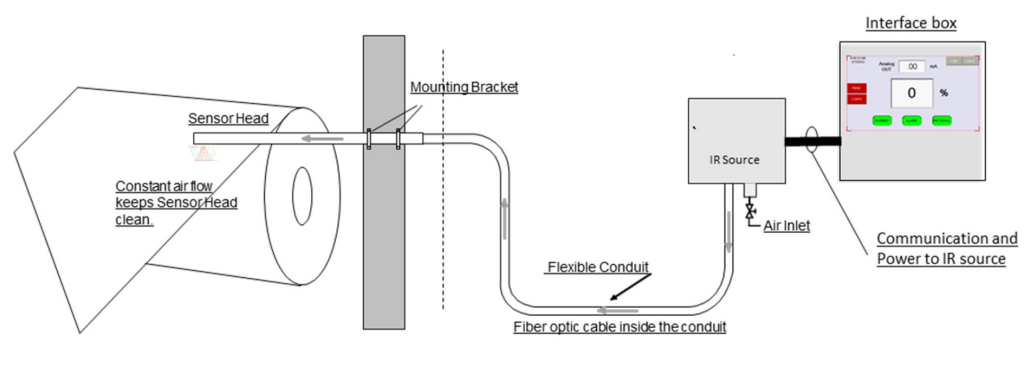

The Rhinoeye is designed to hold up in the toughest of applications. The sensor head can be installed in dusty, steamy locations above or below the sheet. The air purge system keeps the eyes clean and unaffected by high temperatures. Rhinoeye IR Source and Purge System can be located 20 to 30 feet away from the measuring head. The IR source can detect presence or non presence of not only paper but any other surface.

The Rhinoeye digital signal gives an instant response to paper breaks on the machine. This technology is not subject to interference of backlight or indirect light concentrations. The sensor unit sends IR light onto the monitored surface

through a fiber optic cable. The sensor converts the reflected light and is transmitted to the interface box. This signal is

converted to provide dual contact relay outputs and dual 4 to 20 mA signal based off configuration.

Advantages

- Easy to use and set-up interface

- Reliable constant measurement to all breaks

- Suitable for harsh applications that include dust, steam, vibration, or heat

- Performs on any surface material

- Trends break history

Rhinoeye Specifications

- Ambient Temp: Electronics 15° to 140° F; Sensor and Fiber Optic Cable 15° to 350° F

- Fiber Optic Cable: 20 ft or 30 ft

- Fiber Optic Cable Protection: Requires an airtight conduit min ¾” ID

- Conduit connection: 1” NPT

- Installation: Sensor head 2” to 14” from paper

- IR Source response time: 100 µs

- Power Supply: 110 Vac

- Enclosure: NEMA 4

- Purge air: Dry Instrument air 2 to 3 scfm @ 8 to 14 psi

- Digital Output: Dual relay outputs

- Analog Output: One 4 to 20 mA