Integral Calibration, Intelligent Analytics & Predictive Maintenance for Plug & Plug Hot-Swap Operation for Continuous Field Measurements

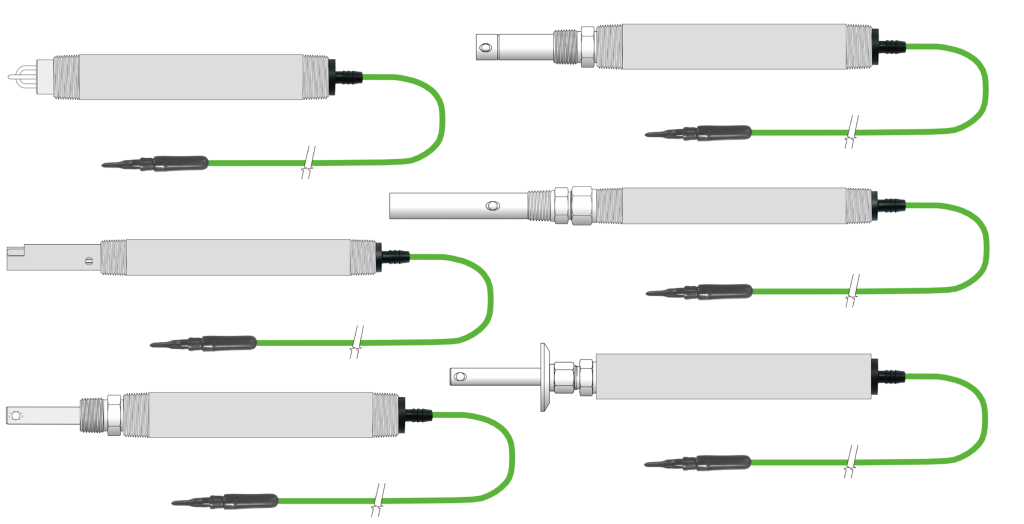

Installation Styles

- Inline

- Immersion

- Submersible

- Sanitary

- HOT-TAP Valve Retractable

- Special installation styles are available upon request as special order configurations (inquire to factory)

Measuring Ranges

- Down to Ultrapure Water ( 0-2 μS/cm | 0-18.2 MΩ )

- Up to 2,000,000 μS/cm ( 2,000 mS/cm )

- Computed Salinity up to 50.000 PSU

- Computed Total Dissolved Solids (TDS) to 100,000 ppm

- Computed Resistivity in MΩ with UPW ATC curve

Operating Modes

- Standard Range & High Range Modes o Can toggle between standard and high range mode while sensor is in use as most appropriate for sample for best resolution and scaling

- Ultralow Range Mode

- With special UPW temperature compensation

Unique Features

- Sensors are supplied precalibrated with certificate ready for immediate field commissioning upon arrival

- Auto configuration of cell constant & range mode for controllers supplied with smart conductivity sensors

- Time since calibration last performed can be used for predictive maintenance to ensure accurate field readings

- Separate span gain calibrations for standard & high range modes for best reading in any operating mode

Materials of Construction

- Electrodes

316SS, Titanium, Hastelloy C-276, Monel - Insulators

CPVC, TEFLON (PTFE), KYNAR (PVDF), PEEK - “O”-Rings

EPDM & EPR, VITON, AFLAS, KALREZ - Compression Fittings

316SS, KYNAR (PVDF), PolyPropylene (PP)

Specifications

- Up to 500 psig

- Up to 205 °C for Inline, Sanitary & HOT-TAP Use

- Process Connections: o Inline from ½”MNPT up to 1”MNPT o Sanitary from ¾” to 2½” TRI-CLOVER Flange

Cell Constants

- Anywhere from K=0.01/cm up to K=20.0/cm

Industrial Smart Digital MODBUS RTU Conductivity Sensors